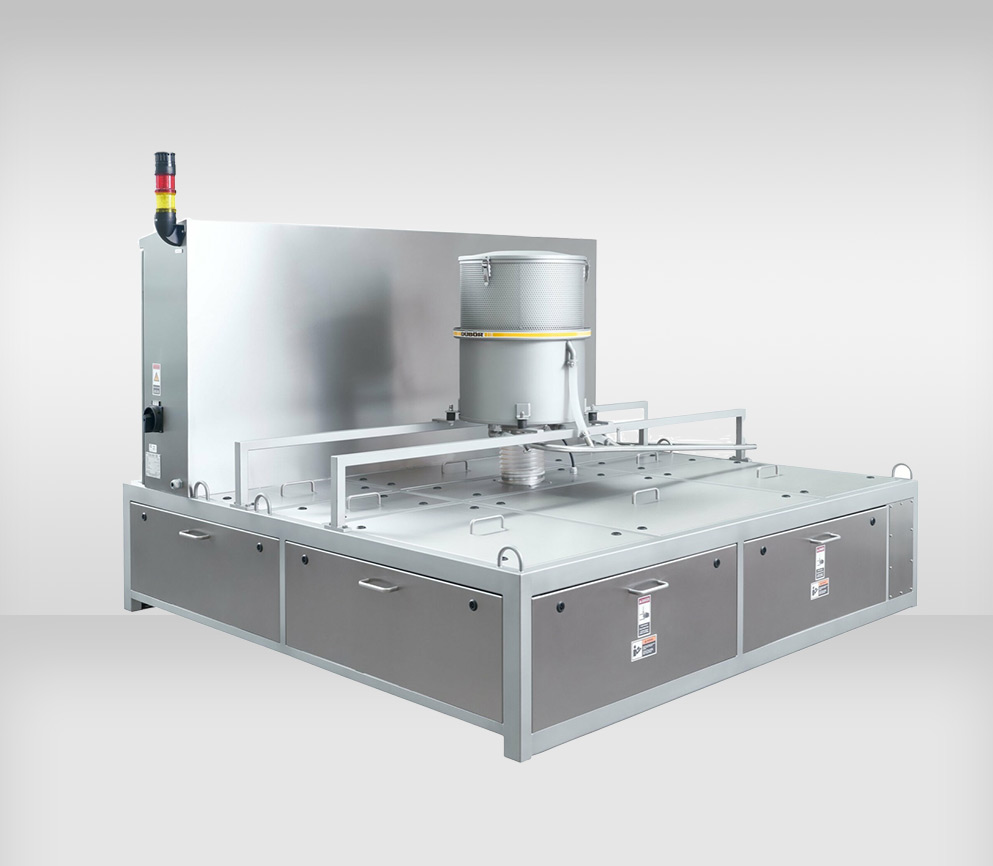

TSA 800

THE UNIVERSAL RELEASE AGENT SPRAY DEVICE FOR ALL SHEETS AND MOLDS

The modular design principle allows for offering the optimal solution for every production requirement.

We adapt to your molds!

Each attachment sprays the baking release agent cleanly and efficiently into your baking molds. The device is housed in a stainless steel metal casing, which contains the electrical and pneumatic parts. An arm with adjustable nozzles allows spraying the release agent into molds of various heights and with different dimensions. The attachment can be mounted onto an existing conveyor without extensive installation. In combination with a stand, the TSA 800 can also be used as a standalone unit with its own conveyor belt.

The filter system prevents oil mist in the workspace, hence ensuring safety and clean cleanliness of your bakery.

The TSA 800 represents a release agent spray technology that meets the highest standards. These machines has been specially optimized in our research and development laboratories in use with our pan release agent.

TECHNICAL DATA

Electr. connection

400 V rotary current, 16 A

Compressed air connection

6 bar, oil-free

Operating pressure

0.1-0.5 bar

Belt speed

Individual

Conveyor dimensions

1,710 mm to 3,000 mm

Conveyor dimensions (width)

500 – 1,000 mm

Operating height

Individual

Spray stations

max. 5 for round moulds, max. 10 for right-angled moulds